ROBUST TOOLS

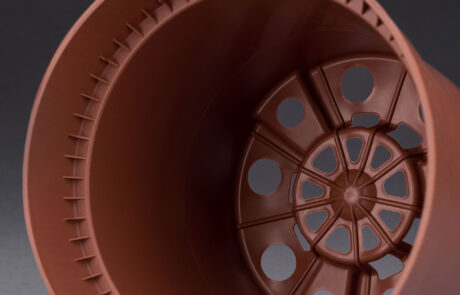

FOR PLANT POTS

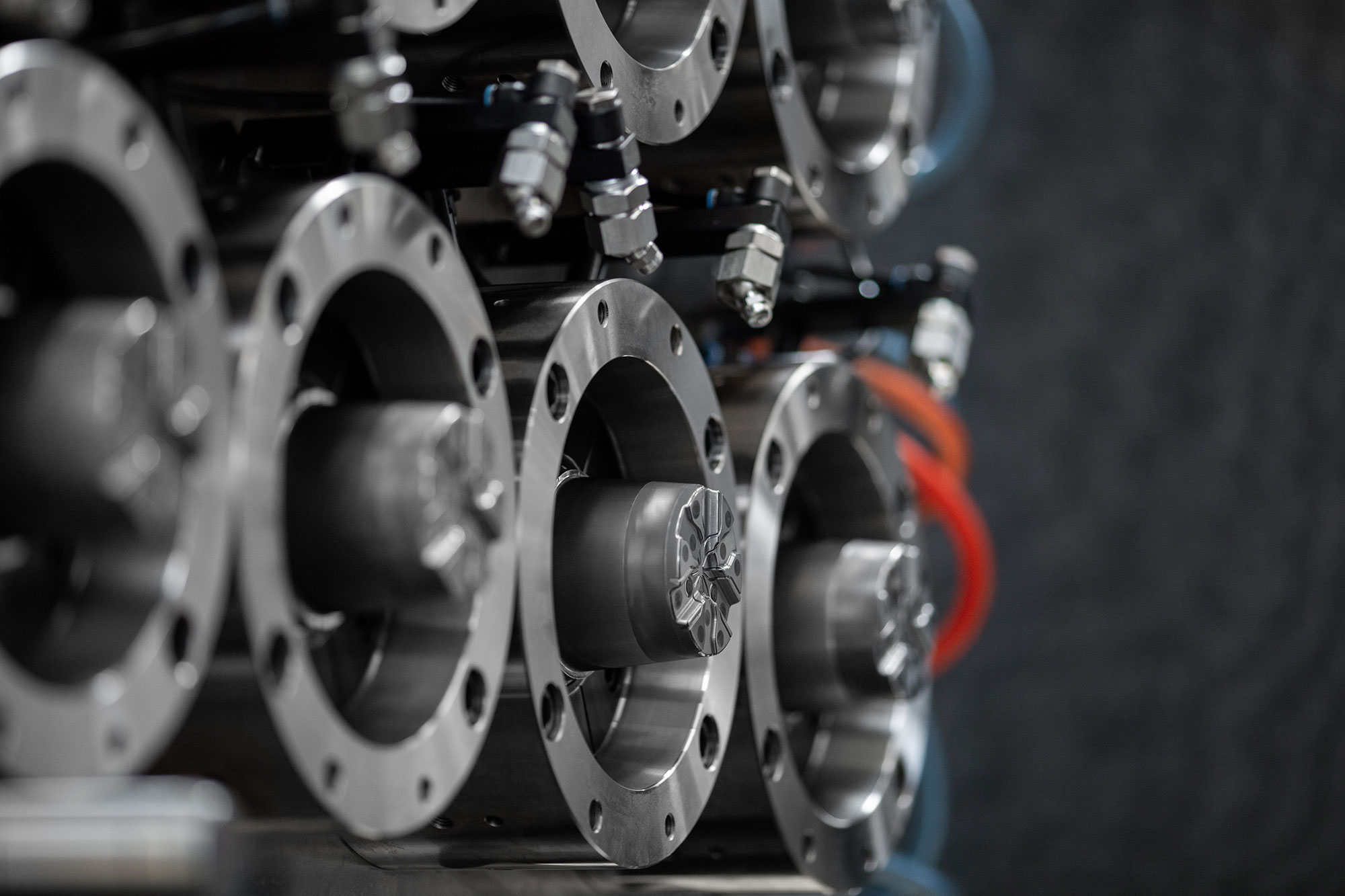

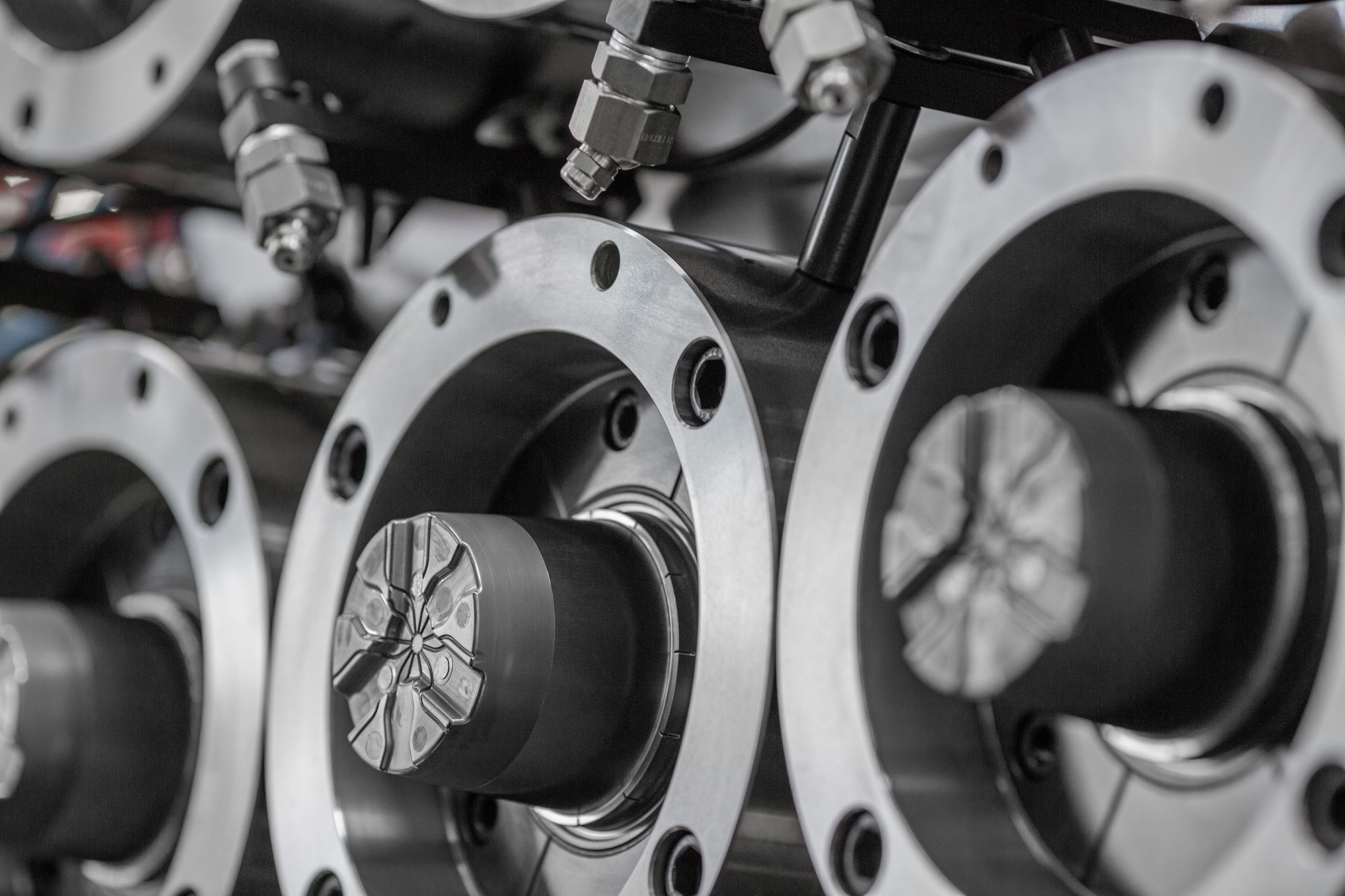

The robustness, precision, and durability of our moulds enable consistent large-volume production of plant pots that meet manufacturing quality requirements for years. Our tools are designed for processing recycled material, permit a service life of many millions of production cycles, and have a robust construction that can handle enormous loads over the long term. This gives our customers minimal downtimes, the shortest cycle times, and ultimately minimal unit costs.

SPECIAL SERVICES

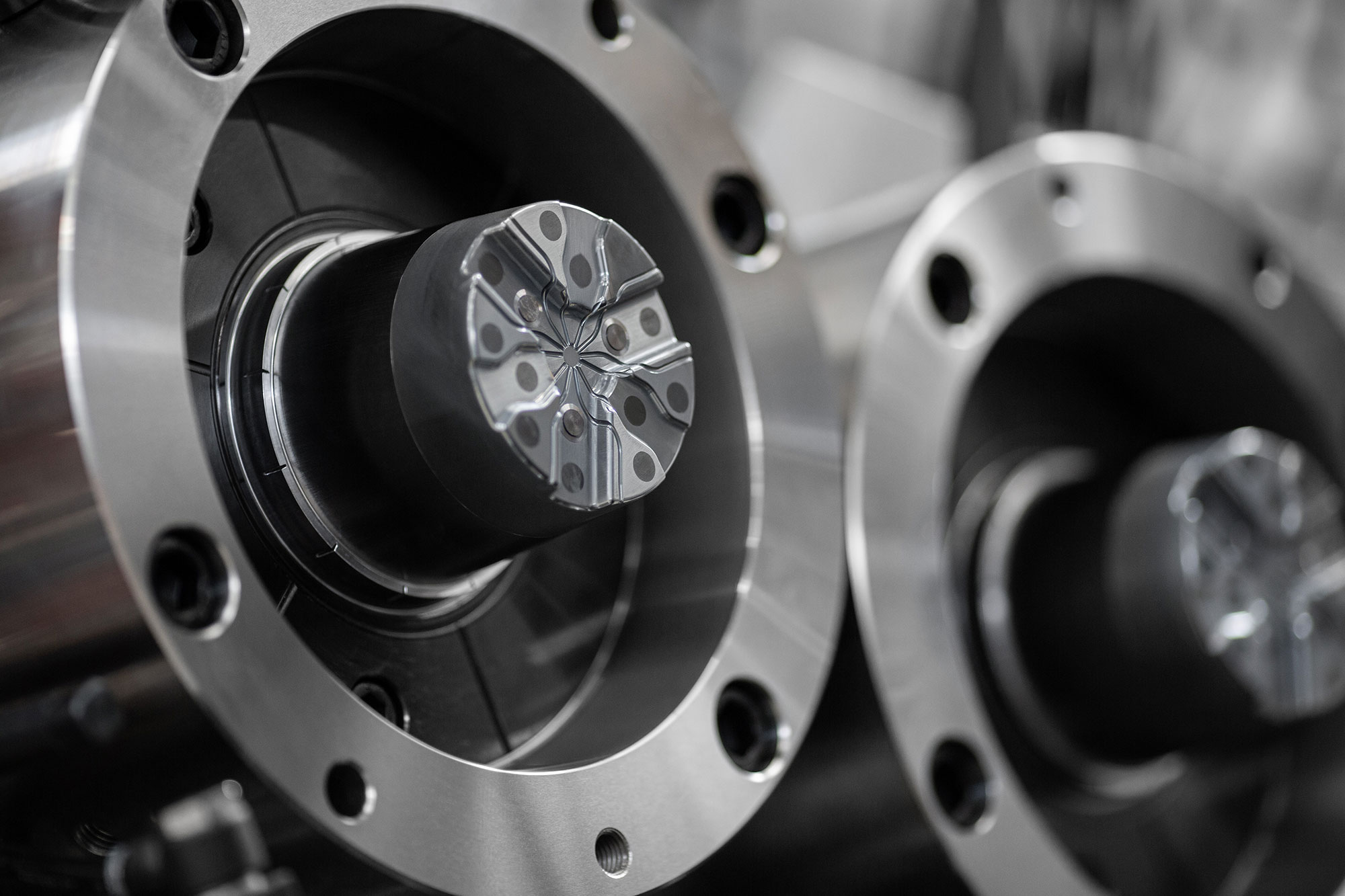

BASE GEOMETRIES

Our highly precise and stable centring solutions and proven designs for embossing and formation of holes enable a very long service life even for complex base geometries.

.

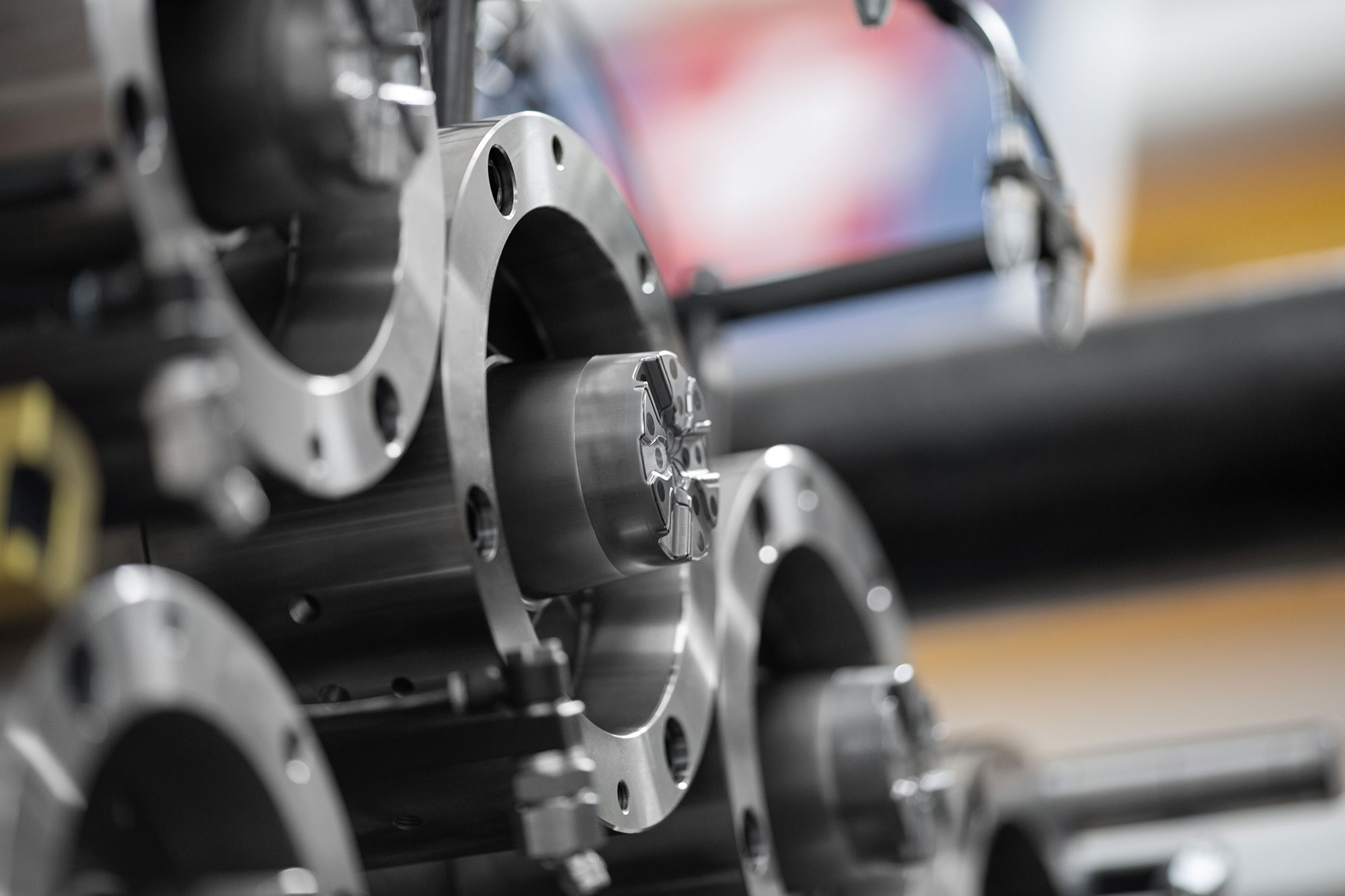

RECYCLED MATERIAL

Minimal wear on the tool is guaranteed by optimal material pairs and coatings and a hot runner system optimized for recycled material.

.

WEIGHT REDUCTION

We offer cost-effective solutions for minimizing piece weight. With experience, creativity, and the latest technology we support our customers in reducing plastic use to the bare minimum.

ADDED VALUE

FOR YOUR PRODUCTION

Our injection moulds enable high-quality, efficient long-term production so that our customers benefit from lower total costs and a much higher return on investment.

Low maintenance costs and ease of use mean our tools are always ready for work

Our tools are rugged, heavy-duty and have very fast production cycles

Our tools reliably deliver reproducible, top-quality results

Solid construction and high-grade materials give our tools a long service life