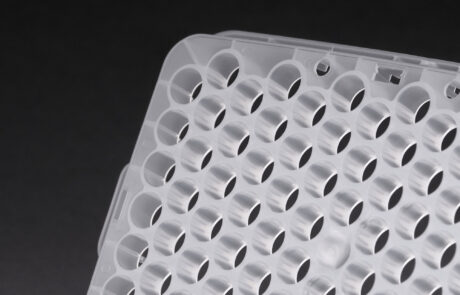

TOOLS WITH HIGHEST PRECISION

FOR MEDICAL DEVICES

Our moulds for medical products meet the most stringent demands for reproducible product quality with narrow tolerances. This also includes the manufacture of complex tools designed for use in a cleanroom. Our comprehensive development know-how yields important preliminary work for an efficient project workflow and excellent quality parts. We offer valuable support with plant integration and validation processes in our modern in-house test centre. The bottom line is that our customers benefit from a faster path to maximum manufacturing quality.

SPECIAL SERVICES

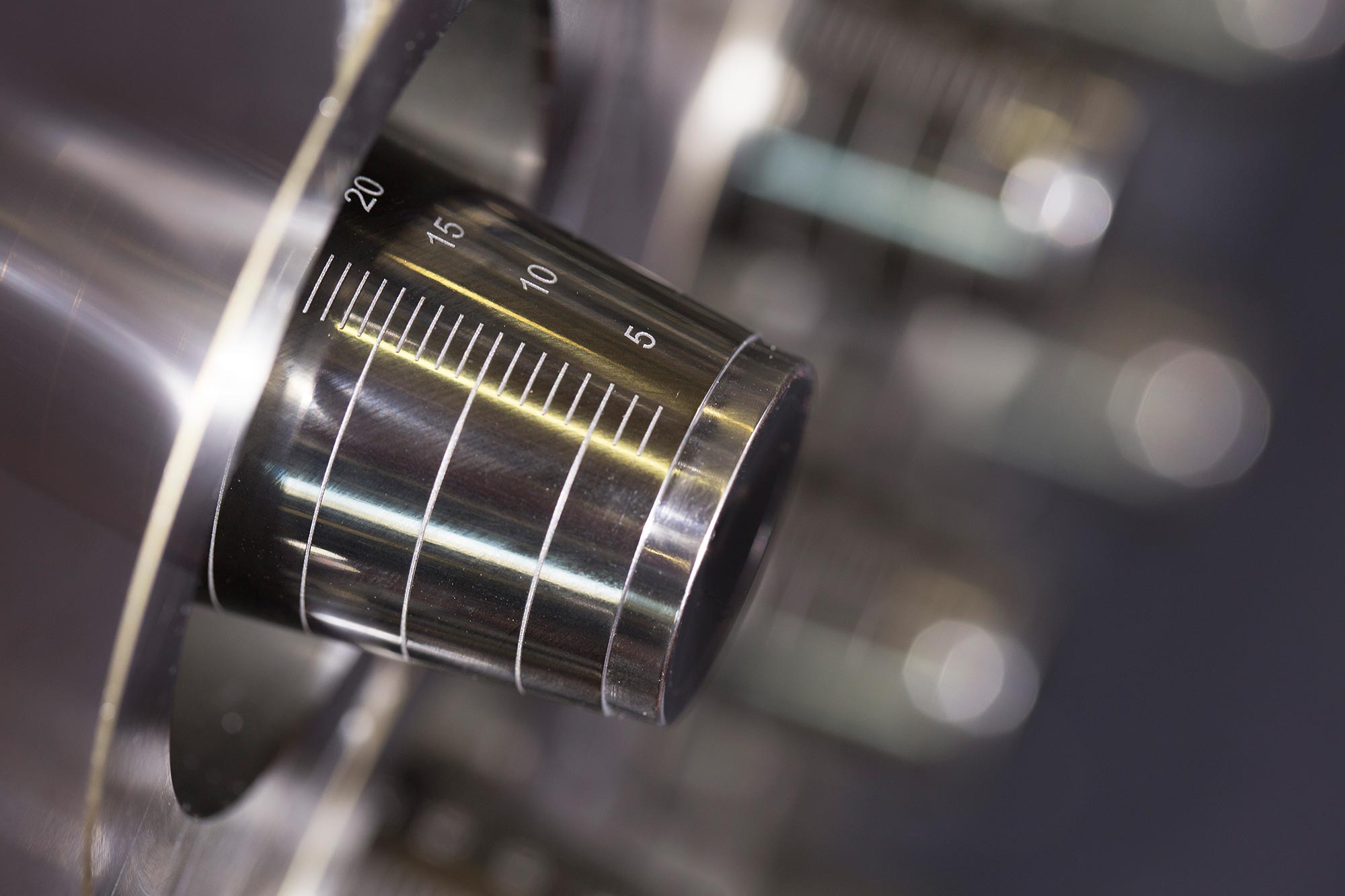

ARTICLE ANALYSIS

With experience and the latest software, we produce article analyses and develop implementation solutions for optimal mould design and superlative manufacturing precision. In this way we can guarantee fast and long term high quality moulds.

.

PRODUCT VALIDATION

In our technical centre we have cutting-edge infrastructure for sampling our tools, from moulded part testing through zero series production and total facility integration.

ADDED VALUE

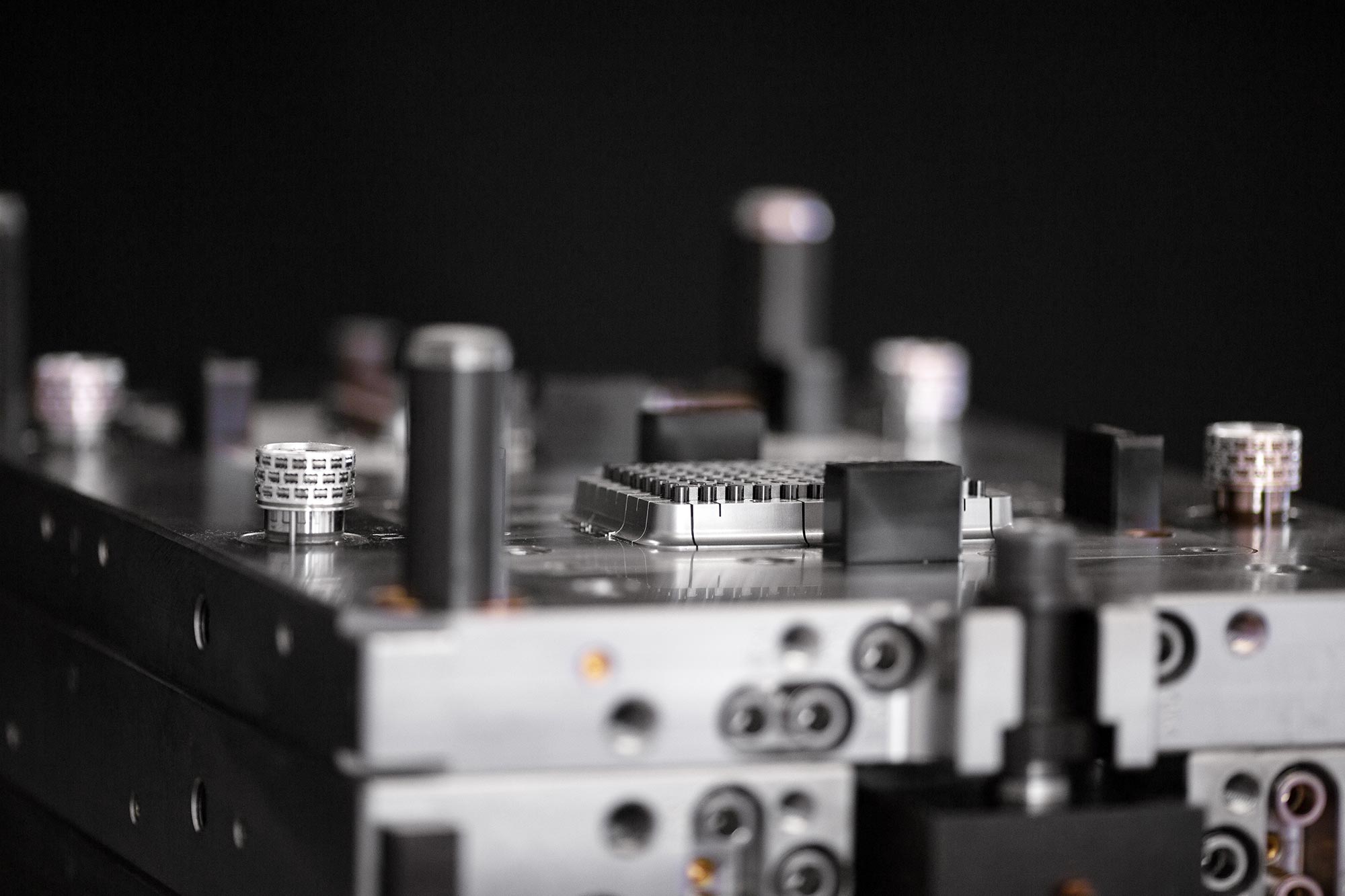

FOR YOUR PRODUCTION

Our injection moulds enable high-quality, efficient long-term production so that our customers benefit from lower total costs and a much higher return on investment.

Low maintenance costs and ease of use mean our tools are always ready for work

Our tools are rugged, heavy-duty and have very fast production cycles

Our tools reliably deliver reproducible, top-quality results

Solid construction and high-grade materials give our tools a long service life